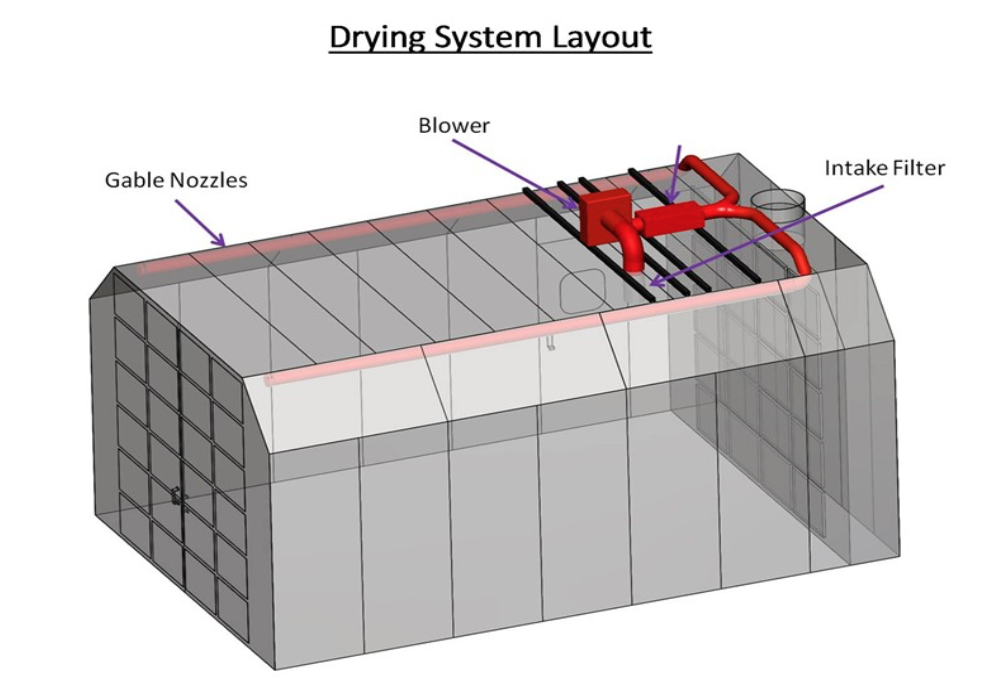

Waterborne Paint Drying System

Pacific Spray Booths is a distributor of California Pulse Paint Drying Systems which recirculate spray booth cabin air.

Spray booth cabin air is filtered then pressurized by a single blower and directed onto the painted surface through 4 corner towers. Spray booth pressure is not affected by the operation of the waterborne paint drying system.

Intake Air / Intake Filter

Intake air is filtered through a paint arresting filter. Spray booth cabin air can be taken trough one of the following methods:

• Air can be taken from the spray booth cabin next to the ceiling filters if it is not a fully filtered ceiling.

• Cabin air can be accessed through the gable in between lights.

• Spray booth cabin air can be taken through the side of the spray booth. The intake filter can be located at the top of a wall panel.

Blower

Air from the cabin is ducted to the intake of a single blower. The blower sits on top of the spray booth. The blower wheel is a forward curved, ‘squirrel cage’ type of blower wheel driven by a 2 hp motor. The blower is designed to deliver the correct combination of pressure and volume for this application.

Pulse Generation / Blast Gates

The air coming out of the blower is directed to the left side two towers or the right side two towers of the booth. The air goes to a pair of two towers for 5 seconds then switched to the other pair of two towers for 5 seconds. We use pneumatically operated blast gates to switch between the right hand side two towers and the left hand side two towers.

Corner Towers

The air is blown onto the painted object through nozzles from the corners of the spray booth. Blowing air from the corners of the booth horizontally is the most efficient way to completely cover the car.

The California Pulse waterborne paint drying system will create air movement and turbulence in door handle indentations, under styling lines, underside of bumpers, etc. Systems that blow air vertically inside the booth will not be able to reach these areas.

Nozzles

The California Pulse nozzles are not user adjustable. Nozzle adjustment of waterborne paint drying systems by the operator is time consuming. Nozzle adjustment introduces the possibility of improper adjustment and inconsistency. If necessary, the nozzles can be adjusted by the installer during installation. Our waterborne paint drying system is designed to cover the center of the spray booth with turbulent air flow without nozzle adjustment. The California Pulse waterborne paint drying system is designed to be a consistently performing production system.

Control Panel

The control panel has and ‘on’ button, ‘off’ button and a selector switch. The waterborne paint drying system will run for the length of time programmed into the cycle timer. Through the selector switch the operator can select to run only the first set of towers, only the second set of two towers, or pulse the system by alternating between the first and second set of towers. When pulsing, the first set of towers is on for 5 seconds then the waterborne paint drying system switches to the second set of towers for 5 seconds.

More Info

Pressure = Reach

Creating high pressure is very important to the proper operation of a waterborne paint drying system. The pressure determines how far the air stream from the nozzles will be projected. If there is no car inside the spray booth, it is imperative to be able to reach the middle of the spray booth with the air stream from the nozzles. The reason is simple: The air stream is used to deliver the turbulence.

Turbulence

Eliminating the boundary layer is the goal of waterborne paint drying systems. Systems accomplish this by creating turbulence on the painted surface. Starting and stopping the airflow creates 300%-400% more turbulencethan just blowing air in a continuous stream!