Ideal For Your Industrial Lighting Needs

Pacific Spray Booths, in greater Vancouver, BC features ideal general industrial lighting for Paint Booths, Assembly Areas and Task Lighting.

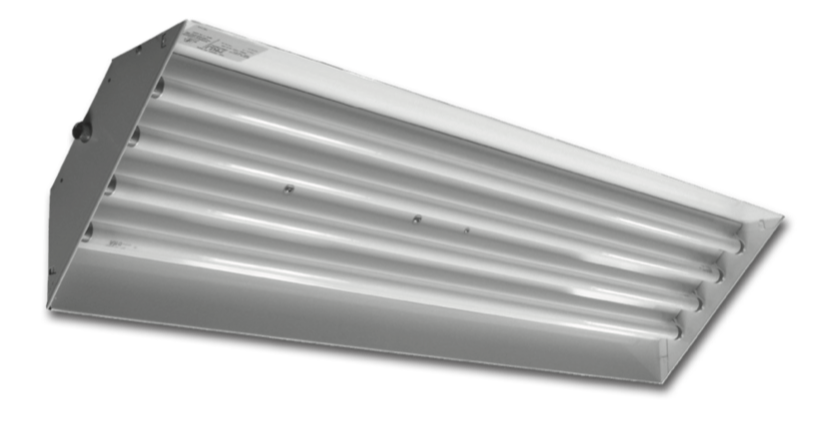

Fabricated with a white powder coat finish the 229H Series is ideal for a variety of industrial lighting needs. A unique hinged ballast cover provides easy access to internal wiring and ballast for installation or service without the need to remove lamps. The 229H uses a 5 Ft. 3-wire whip which reduces installation time by not having to open the fixture. Available in T8, T8HO, or T5HO lamps. Lamps not included.